A comprehensive knowledge of injection molding magnetic rings, you need to understand it when using it

Release time:

2023-07-08

Source:

Injection molded magnets are permanent magnets made by mixing magnetic powder and binder into granules, and then using injection molding technology. Combining high magnetic performance with excellent mechanical properties, providing multiple characteristics and advantages, it can be produced according to customer specifications to meet magnetic, mechanical, and environmental requirements. Adhesive materials can be selected from nylon 6, nylon 12, and PPS, and magnetic materials can be selected from ferrite, neodymium iron boron, samarium cobalt, and their mixtures. Today, the editor will introduce the common knowledge and skills of injection molding magnetic rings.

Advantages of injection molding magnets:

Compared to other manufacturing methods for permanent magnets, injection molding has unique and irreplaceable advantages.

Like plastic products, injection molding can produce magnets with complex shapes; Shaped parts can have unique dimensions, shapes, magnetic and mechanical properties.

2. The injection molding process can use "embedded molding", "multi-step molding", and "multi workpiece molding" to integrate the magnet with other components, thereby saving the cost of secondary processing and assembly.

3. Injection molding technology can produce both isotropic and anisotropic magnets. During the formation of anisotropic magnets, an external orientation magnetic field is required to give the magnetic powder a certain orientation in the molten polymer, that is, orientation occurs, and multipole magnetization can be achieved.

4. The injection molding process ensures good consistency in size and performance of the product, and the product shapes are diverse.

Due to the high content of polymer binder in injection molded magnets, the magnets themselves have strong corrosion resistance and usually do not require surface coating protection

6. High strength magnetism and excellent mechanical properties

Compared with sintered magnets, injection molded magnets have better crack resistance and are easier to assemble; The embedded molding process can directly inject magnetic powder material onto the product to form components

8. Magnets can be fully magnetized or partially magnetized and demagnetized

The adhesive and magnet used can meet the application temperature range of -40 ℃ to 180 ℃.

key word:

Related information

2023-07-10

2023-07-10

2023-07-08

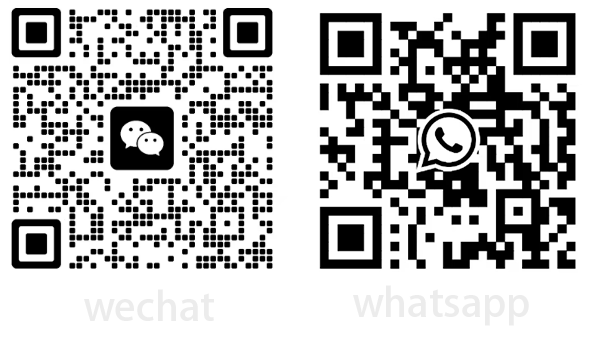

Follow us

Huizhou Juli Precision Plastic Magnetic Co., Ltd

mobile phone:+86 13927316845

Telephone:+86 +86 0752-6831178

Company email:Winson@julimagenetic.com

Company Address: Dajing Group, Dajing Village, Luoyang Street, Boluo Count,Huizhou,Guangdong Province,,China

Copyright © Huizhou Juli Precision Plastic Magnetic Co., Ltd. All rights reserved