Types, Basic Knowledge, and Applications of Magnets

Release time:

2018-03-19

Source:

Types, Basic Knowledge, and Applications of Magnets

1、 There are many types of magnets, generally divided into two categories: permanent magnets and soft magnets. Permanent magnets are further divided into two categories:

The first category includes metal alloy magnets such as neodymium iron boron magnets, samarium cobalt magnets, and aluminum nickel cobalt magnets.

The second major category is ferrite permanent magnet materials

1. Ferrite magnet: The main raw materials of ferrite include BaFe12O19 and SrFe12O19. Made by ceramic technology,

The texture is relatively hard and belongs to brittle materials. Due to its good temperature resistance, low price, and moderate performance, ferrite magnets have become widely used

Widely used permanent magnets.

2. Neodymium iron boron magnet: Neodymium iron boron is a commercially available magnet known as the magnetic king, with extremely high performance

The magnetic energy product (BHmax) of magnetic properties is more than 10 times higher than that of ferrite. Its mechanical processing performance is also quite good

The working temperature can reach 200 degrees Celsius. And its texture is hard, its performance is stable, and it has a good cost-effectiveness, so its application is extremely

Widely. But because of its strong chemical activity, surface coating treatment is necessary. (such as Zn, Ni plating, electrophoresis, passivation, etc.).

3. Samarium cobalt magnets (SmCo) are classified into SmCo5 and Sm2Co17 based on their composition. Due to the high price of samarium cobalt materials

Development is restricted. SmCo magnets, as rare earth permanent magnets, not only have a high magnetic energy product (14-28MGOe), but also can

Relying on coercivity and good temperature characteristics. Compared with neodymium iron boron magnetic steel, samarium cobalt magnets are more suitable for working in high-temperature environments.

4. Aluminum nickel cobalt magnet: Aluminum nickel cobalt is an alloy composed of aluminum, nickel, cobalt, iron, and other trace metal elements. Foundry worker

Art can be processed and produced into different sizes and shapes, with good processability. Casting aluminum nickel cobalt permanent magnets has a reversible temperature coefficient,

The working temperature can reach over 600 degrees Celsius. Aluminum nickel cobalt permanent magnet products are widely used in various instruments and other application fields.

2、 The magnetic force is arranged as follows: neodymium iron boron magnet, samarium cobalt magnet, aluminum nickel cobalt magnet, ferrite magnet.

NdFeB magnet

Characteristics: Neodymium iron boron permanent magnet material is a permanent magnet material based on the intermetallic compound Nd2Fe14B. Neodymium iron boron has extremely high

The advantages of magnetic energy product and correction force, as well as high energy density, have made neodymium iron boron permanent magnet materials widely used in modern industry and electronic technology

This makes it possible to miniaturize, lightweight, and thin equipment such as instruments, electroacoustic motors, magnetic separation and magnetization.

Material characteristics: The advantages of neodymium iron boron are high cost-effectiveness and good mechanical properties; The drawback is that the Curie temperature point is low,

Poor temperature characteristics and easy powdering corrosion require improvement through adjusting its chemical composition and adopting surface treatment methods

Can meet the requirements of practical applications.

Manufacturing process: The production of neodymium iron boron adopts powder metallurgy technology.

Process flow: Ingredients → Smelting and making ingots → Powder production → Molding → Sintering and tempering → Magnetic testing → Grinding processing →

Sales cutting processing → electroplating → finished product.

ferrites

Characteristics of ferrite magnets: Its main raw materials include BaFe12O19 and SrFe12O19. Made by ceramic craftsmanship, of high quality

The ground is relatively hard and belongs to brittle materials. Due to its good temperature resistance, low price, and moderate performance, ferrite magnets have become a popular choice

For a wide range of permanent magnets.

Characteristics of ferrite magnets: They have high magnetic properties, good time stability, and low temperature coefficient.

Application places of ferrite magnets: widely used in electric meters, instruments, motors, automatic control, microwave devices, radar, and medical applications

Equipment, etc.

The magnetization direction of ferrite magnets can be axial, radial, or as required.

Ferrite magnet shapes: can be produced in cylindrical, circular, rectangular, flat, tile, and axe shapes.

alnico

Characteristics of aluminum nickel cobalt magnet: It is an alloy composed of aluminum, nickel, cobalt, iron, and other trace metal elements. Casting process can

It can be processed and produced into different sizes and shapes, with good processability. Casting aluminum nickel cobalt permanent magnets has a reversible temperature coefficient and works

The temperature can reach over 600 degrees Celsius. Aluminum nickel cobalt permanent magnet products are widely used in various instruments and other application fields.

Aluminum nickel cobalt magnets can be classified into two categories: cast aluminum nickel cobalt and sintered aluminum nickel cobalt.

Application places of aluminum nickel cobalt: Casting aluminum nickel cobalt products are mainly used in automotive parts, instruments and meters, acoustics, motors, and teaching

In fields such as aerospace, aviation, and military, it has the advantages of low temperature coefficient, high temperature resistance, moisture resistance, resistance to oxidation, and good working stability

Sintered aluminum nickel cobalt is produced by powder metallurgy and is suitable for producing products with complex shapes, light, thin, and small sizes. It is widely used

Used for instruments, communication, magnetic switches, and various sensors.

Aluminum nickel cobalt magnets can be produced in cylindrical, circular, rectangular, flat, tile, and horseshoe shapes.

Samarium cobalt magnet

Samarium cobalt magnet, also known as samarium cobalt magnet steel, samarium cobalt permanent magnet, samarium cobalt permanent magnet, samarium cobalt strong magnet, rare earth cobalt permanent magnet, etc. It is from

Samarium, cobalt, and other rare earth materials are proportioned, melted and refined into alloys, and then crushed, pressed, and sintered to produce a magnetic material,

With high magnetic energy product and extremely low temperature coefficient, the working temperature can reach 350 ℃, and there is no limit to negative temperature. When the working temperature is above 180 ℃

Its magnetic energy product, temperature stability, and chemical stability all exceed those of neodymium iron boron permanent magnet materials. Has strong corrosion and oxidation resistance

Sex; So it is widely used in aerospace, national defense and military industry, microwave devices, communication, medical equipment, instruments, meters, and various magnetic fields

Sexual transmission devices, sensors, magnetic processors, motors, magnetic cranes, etc.

Production Process of samarium cobalt magnet: ingredients → smelting and ingot making → powder making → pressing → sintering and tempering → magnetic testing →

Grinding processing → Pin cutting processing → Finished product

Typical shapes of samarium cobalt magnets: circular, round, square, square bar, tile shaped, and special shapes can be processed according to specific requirements.

key word:

Related information

2023-07-10

2023-07-10

2023-07-08

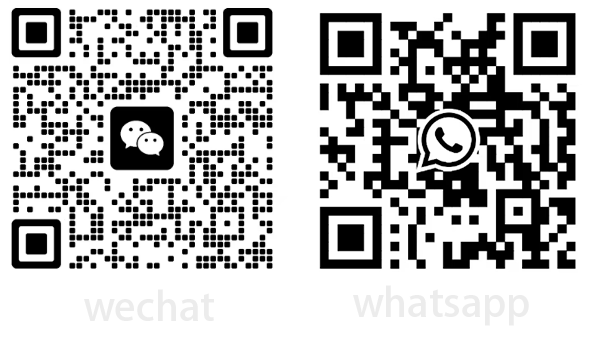

Follow us

Huizhou Juli Precision Plastic Magnetic Co., Ltd

mobile phone:+86 13927316845

Telephone:+86 +86 0752-6831178

Company email:Winson@julimagenetic.com

Company Address: Dajing Group, Dajing Village, Luoyang Street, Boluo Count,Huizhou,Guangdong Province,,China

Copyright © Huizhou Juli Precision Plastic Magnetic Co., Ltd. All rights reserved